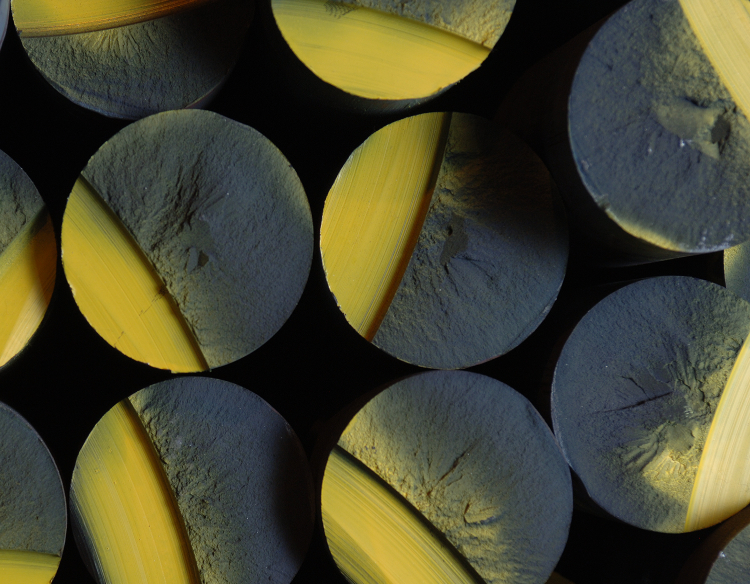

Dura-Bar G1A contains Type D graphite in a predominantly ferrite matrix. This specification was originally developed for the glass mold industry where fine grain structure and superior machining finish are needed. Dimensional growth due to repeated heating and cooling cycles is minimal due to the smaller graphite flake and size and ferritic matrix structure.

Blank Molds, Plungers

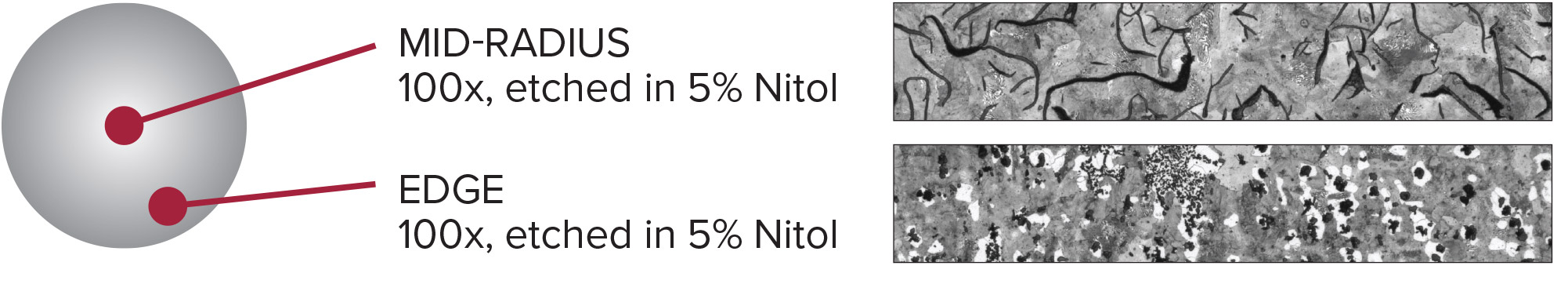

The microstructure will contain Type VII, size 6-8 graphite as defined in ASTM A247. The matrix is predominantly ferrite. Chill carbides will be less than 5% in any field at 100x and will be well dispersed.

Carbon and silicon targets are specified for each bar size in order to control the size and shape of the graphite flake. Titanium is added as an inoculant in order to produce the Type D graphite structure.

| Element | Percentage |

|---|---|

| Carbon | 2.60 - 3.75% |

| Silicon | 2.30 - 3.00% |

| Manganese | 0.10 - 0.35% |

| Sulfur | 0.025% Max |

| Phosphorus | 0.10% Max |

Brinell hardness values for nominal as-cast diameters are shown in the table. Hardness properties listed are minimum, maximum across the bar. Hardness values for rectangles and squares are a function of the height and width ratios and will be supplied on request.

Size Ranges

| Inches | Millimeters |

|---|---|

| 1.000 - 1.500 | 25 -38 |

| 1.501 - 3.000 | 38 - 76 |

| 3.001 - 7.000 | 76 - 178 |

BHN

| Min | Max |

|---|---|

| 159 | 229 |

| 156 | 201 |

| 143 | 201 |

The tensile strength will be approximately 25,000 psi, as determined from a longitudinal test specimen taken from mid-radius of the as-cast bar. The tensile data is not a minimum, but rather the typical expected tensile strength. Anticipated tensile data for shapes, including squares and rectangles, will be provided on request.

| Mechanical Properties | |

|---|---|

| Tensile strength psi (min) | 25,000 |

| Yield strength psi (min) | n/a |

| Elongation (min) | n/a |