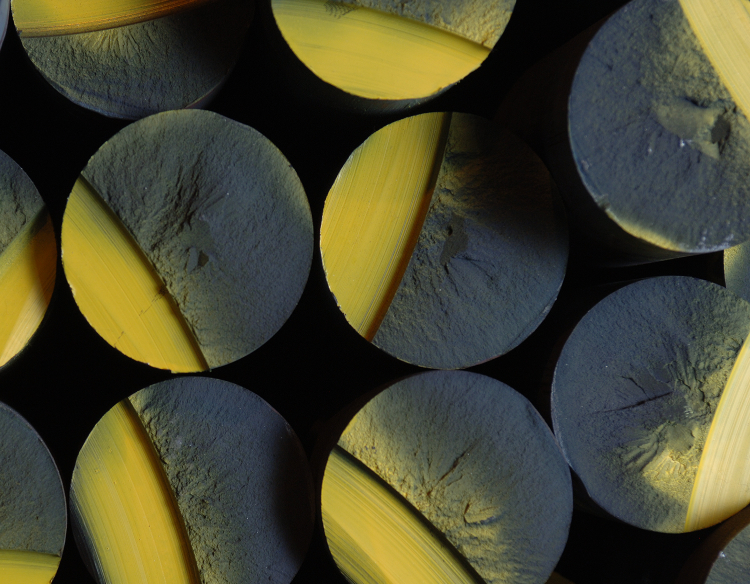

Dura-Bar G2A contains type D graphite in a predominantly pearlitic matrix. The fine graphite structure allows excellent surface finish and is normally used in permanent mold applications requiring optimal strengths and wear resistance.

Blank Molds, Plungers

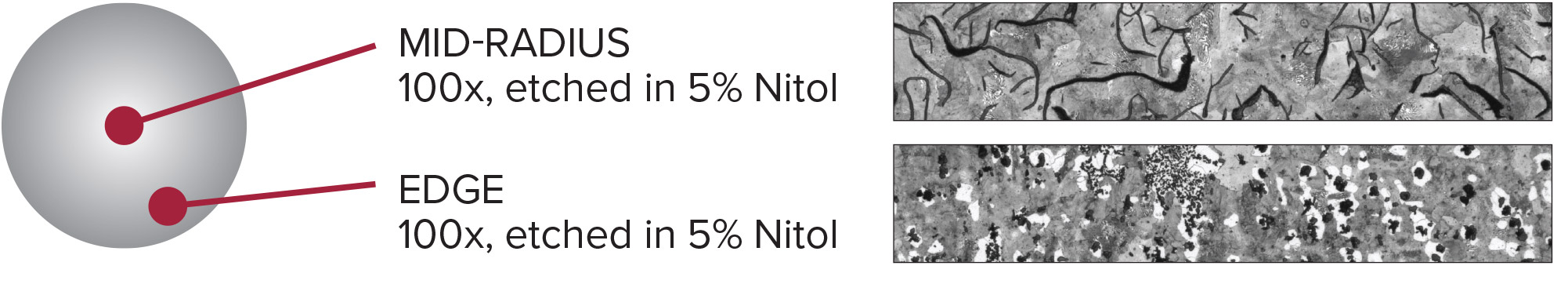

The microstructure will contain Type VII, D, size 6-8 graphite as defined in ASTM A247. The matrix is predominantly pearlite. The edge or rim will be similar to the center. Chill carbides will be less than 5% in any field at 100x and will be well dispersed.

Carbon and silicon targets are specified for each bar size in order to maintain mechanical properties. Titanium is added as an inoculant to produce the Type D graphite structure.

| Element | Percentage |

|---|---|

| Carbon | 2.60 - 3.75% |

| Silicon | 2.30 - 3.00% |

| Manganese | 0.20 - 0.40% |

| Sulfur | 0.025% Max |

| Phosphorus | 0.12% Max |

Brinell hardness values for nominal as-cast diameters are shown in the table. Hardness properties listed are minimum, maximum across the bar. Hardness values for rectangles and squares are a function of the height and width ratios and will be provided on request.

Size Range

| Inches | Millimeters |

|---|---|

| 0.750 - 20.000 | 16 - 508 |

BHN

| Min | Max |

|---|---|

| 248 | 311 |

The tensile strength will be approximately 40,000 psi, as determined from a longitudinal test specimen taken from mid-radius of the as-cast bar. The tensile data is not a minimum, but rather the typical expected tensile strength. Anticipated tensile data for shapes, including squares and rectangles, will be provided on request.

| Mechanical Properties | |

|---|---|

| Tensile strength psi (min) | 40,000 |

| Yield strength psi (min) | n/a |

| Elongation (min) | n/a |